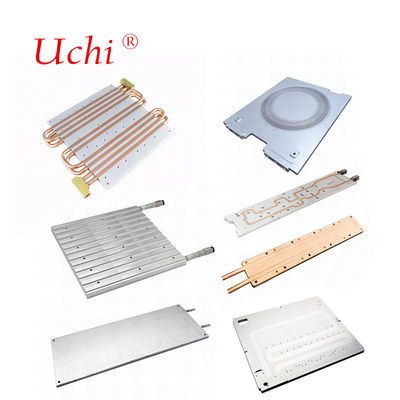

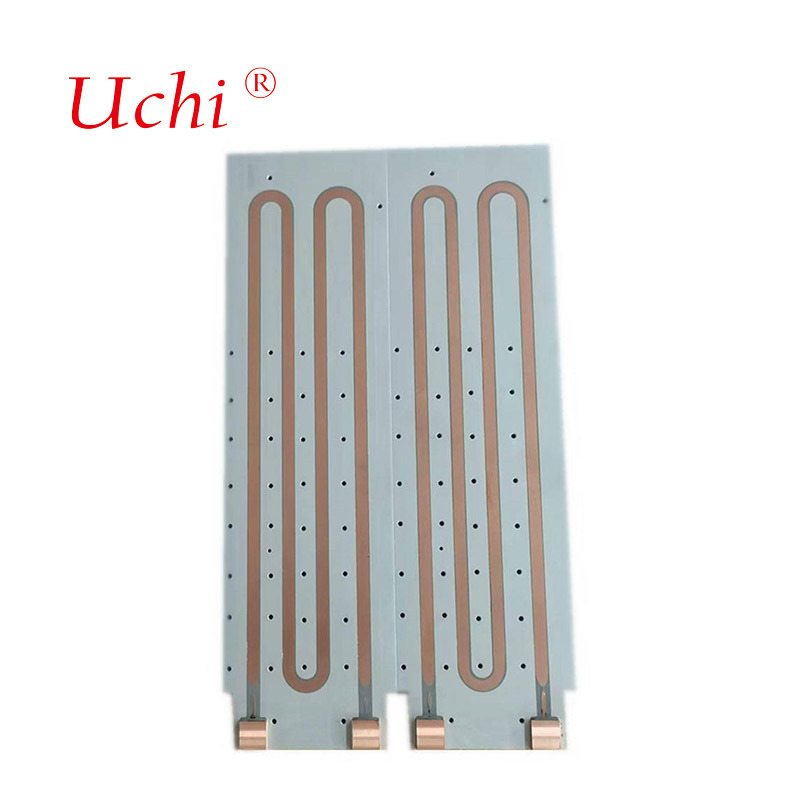

Piastra fredda in alluminio raffreddata ad acqua per la lavorazione CNC della dissipazione del calore del tubo di rame per apparecchiature industriali

Dettagli:

| Luogo di origine: | Dongguan , Guangdong, Cina |

| Marca: | Uchi |

| Certificazione: | SMC |

| Numero di modello: | piastra fredda raffreddata ad acqua-21 |

Termini di pagamento e spedizione:

| Quantità di ordine minimo: | 100pcs |

|---|---|

| Prezzo: | Negoziabile |

| Termini di pagamento: | T/T , PayPal , Western Union, MoneyGram |

| Capacità di alimentazione: | 50000000pcs al mese |

|

Informazioni dettagliate |

|||

| Caratteristica: | Alta potenza | Tipo: | Brocciatura, FORATURA, Lavorazione Laser, Fresatura, Altro... |

|---|---|---|---|

| Materiale: | Alluminio 6061, tubo di rame | Forma: | Piazza |

| Certificato: | ISO 9001:2008,ISO 14001:2004, ROHS | Processo extra: | MACCHING CNC |

| Fine: | Pulito + anodizzato | Misurare: | Dimensioni personalizzate |

| Applicazione: | Fonte luminosa laser RGB | ||

| Evidenziare: | Placca fredda di alluminio raffreddata ad acqua,piastra di dissipazione del calore del tubo di rame,piastra di raffreddamento a liquido industriale |

||

Descrizione di prodotto

Piastra fredda in alluminio ad alte prestazioni progettata per la lavorazione CNC della dissipazione del calore del tubo di rame in applicazioni di apparecchiature industriali.

| Tipo di attività | Fabbrica / Produttore |

|---|---|

| Prodotti |

|

| Tipo | Dissipatori di calore |

| Servizio | Servizio OEM con supporto R&S professionale |

| Materiale | Alluminio/rame |

| Costo degli utensili | Non necessario |

| Processo | Taglio, scanalatura, estrusione, stampaggio, laminazione, alesatura, punzonatura, foratura, piegatura, saldatura, fresatura, tornitura, lavorazione CNC, rettifica, sbavatura, pulizia, ispezione al 100%, imballaggio, consegna |

| Trattamento superficiale | Lucidatura, anodizzazione, verniciatura a polvere, passivazione, verniciatura, placcatura, sabbiatura, e-coating e altri su richiesta |

| Dimensione | Personalizzato (Dimensione massima: L 1200 × L 3500mm) |

| Ispezione | CMM, Strumento di misurazione bidimensionale, Proiettore, Misuratore di planarità, Misuratore di rugosità, Apparecchiatura di prova delle perdite di elio |

| Tempi di consegna | Tempi di consegna del campione: 15-21 giorni. Tempi di consegna della produzione: 25 giorni. |

- Fotovoltaico

- Energia eolica

- Comunicazioni

- LED

- Veicoli elettrici

- Medico

- Trasporto ferroviario

- Industria militare

- Microonde

- Automobile

- Laser

- Inverter solare ad alta potenza

- Luce LED ad alta potenza

- Data Center

- Raffreddamento IGBT

- Saldatrice

- Intelligenza artificiale

Il nostro processo di produzione comprende progettazione di disegni, lavorazione CNC, saldatura a frizione, brasatura, assemblaggio, scanalatura ed estrusione, test e trattamento superficiale per garantire soluzioni di dissipazione del calore di alta qualità.

I nostri dissipatori di calore e piastre fredde ad acqua sono ampiamente utilizzati nei trasporti, nei computer CPU, nei server, nell'illuminazione a LED, nelle apparecchiature laser, nell'aria condizionata e in altri prodotti elettrici che generano calore.

Quando si progettano dissipatori di calore o radiatori termici, i nostri prodotti possono soddisfare le vostre esigenze specifiche.