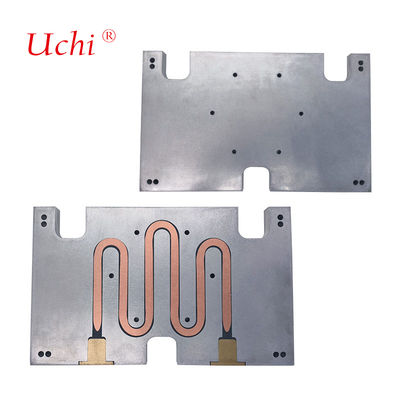

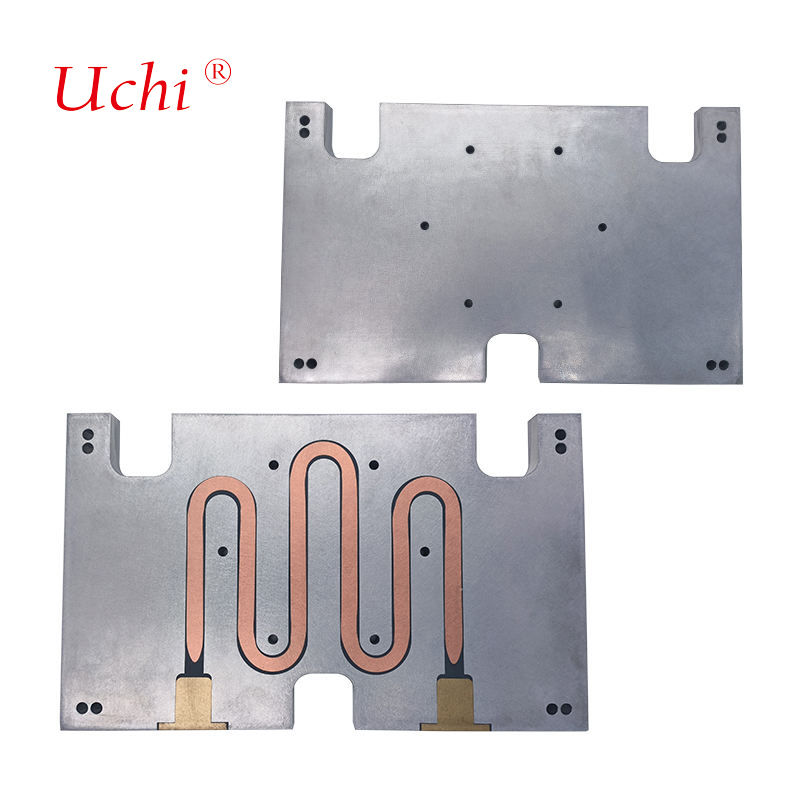

Piastra di raffreddamento a liquido IGBT personalizzata Piastra di raffreddamento in alluminio Piastra fredda ad acqua, Piastra di raffreddamento a liquido

Dettagli:

| Luogo di origine: | Dongguan , Guangdong, Cina |

| Marca: | Uchi |

| Certificazione: | SMC |

| Numero di modello: | Piastra di raffreddamento a liquido 12 |

Termini di pagamento e spedizione:

| Quantità di ordine minimo: | 100pcs |

|---|---|

| Prezzo: | Negoziabile |

| Termini di pagamento: | T/T, PayPal, Western Union, MoneyGram |

| Capacità di alimentazione: | 50000000pcs al mese |

|

Informazioni dettagliate |

|||

| Materiale: | Lega di alluminio | Pressione di esercizio: | Da 1,2 a 5 bar |

|---|---|---|---|

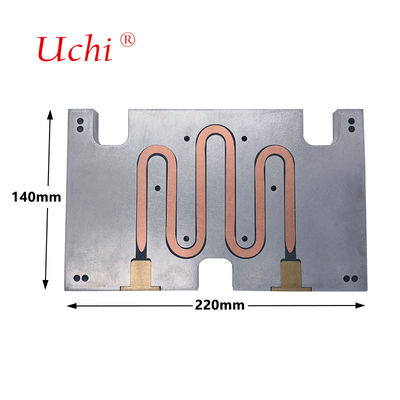

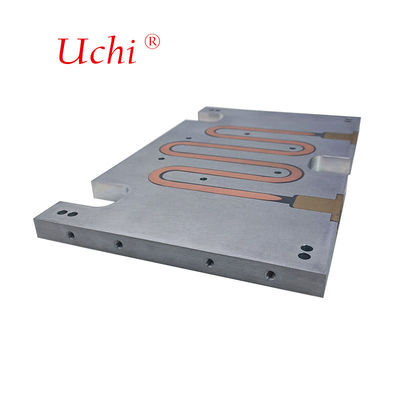

| Finitura superficiale: | Finitura al mulino o anodizzazione | Misurare: | 220*140*35 mm o dimensioni personalizzate |

| Dimensione del pacchetto singolo: | 23X15X4 cm | Peso lordo singolo: | 2.400 chilogrammi |

| Garanzia: | 1 anno | Rugosità superficiale: | 1,2 um |

| Piattenezza superficiale: | Al di sotto di 0,005 cm/cm | ||

| Evidenziare: | piastra di raffreddamento a liquido IGBT personalizzata,Piastra fredda ad acqua in alluminio,piastra di raffreddamento liquido con garanzia |

||

Descrizione di prodotto

Piastra di raffreddamento a liquido IGBT personalizzata in alluminio

La nostra piastra fredda in alluminio è lavorata da una lega di alluminio di alta qualità, offrendo una dissipazione del calore ottimale per i moduli IGBT. Con una conducibilità termica di circa 202 W/(m*K), queste piastre offrono prestazioni eccellenti riducendo al contempo il peso e i costi del sistema rispetto alle alternative in rame.

Vantaggi dei materiali

La lega di alluminio offre vantaggi significativi per le applicazioni di raffreddamento a liquido:

- Conveniente a 1/3 o 1/4 del prezzo del rame

- Leggero con una densità di 2,7 g/cm³ (contro 8,9 g/cm³ per il rame)

- Può essere fabbricato in complesse strutture a canali di flusso

- Resiste alla corrosione del refrigerante mantenendo una conducibilità termica stabile

Specifiche del prodotto

| Materiali | Rame (1020/1100), Alluminio (1060/1070/6063/6061) |

|---|---|

| Trattamento superficiale | Placcatura, Rivestimento, Verniciatura, Anodizzazione, Sabbiatura, Maschiatura, Sbavatura, Cromatura, Marcatura laser, Sgrassaggio, Passivazione, Pulizia |

| Lavorazione | Lavorazione CNC, Estrusione, Taglio, Forgiatura a freddo, Pressofusione, Stampaggio, Skiving, Piegatura, Inserimento, FSW (Saldatura a frizione-mescolamento), Saldatura, Epossidica, Nichelatura, Piegatura, Saldatura, Taglio trasversale, Fresatura, Foratura |

| Dimensione | Dimensione personalizzata o disegno del cliente richiesto |

| Applicazione | Illuminazione a LED, Inverter solare, Apparecchiature di alimentazione, Ventilatore medicale, IGBT, Automotive elettrico, Raffreddamento a liquido per desktop, Dispositivo di comunicazione, Dissipatore di calore CPU, Apparecchiature industriali |

| Disegno accettato | AutoCAD (dxf, dwg), PDF, 3D (STEP/IGS) |

Tecnologia di brasatura avanzata

Il nostro processo di brasatura sottovuoto unisce piastre di alluminio utilizzando un metallo d'apporto con un punto di fusione inferiore rispetto al materiale di base, creando giunti estremamente resistenti senza flusso corrosivo residuo. Questa tecnologia di fascia alta offre un riscaldamento uniforme, un controllo preciso della temperatura ed elimina i requisiti di pulizia successivi, riducendo al minimo la distorsione delle parti.

Applicazioni chiave

- Laser e apparecchiature mediche

- Raffreddamento del pacco batteria di alimentazione EV

- Elettronica di potenza e dispositivi di azionamento del motore

- Sistemi di trasmissione 5G a microonde

- Sistemi di energia rinnovabile

- IGBT e sistemi a semiconduttore di potenza

- Data center e applicazioni di alimentazione industriale

- Sistemi di difesa e avionica

- Celle a combustibile e sistemi di trazione

Capacità di produzione

Il nostro stabilimento di produzione comprende 25 macchine CNC, 10 macchine per stampaggio, 2 macchine per saldatura a frizione, 2 grandi soffiatori termici, 4 macchine per il taglio a filo, 2 macchine a scintilla, 4 frese e 3 rettificatrici.

Controllo qualità

Manteniamo rigorosi standard di qualità con 1 macchina di misura a coordinate, 1 strumento proiettore, 2 macchine per test ad alta pressione dell'acqua, 4 macchine per test di resistenza termica e 2 macchine per test di tenuta ai liquidi.

Servizio clienti

- Risposta rapida a tutte le richieste

- Prezzi competitivi con qualità garantita

- Programmazione efficiente della produzione

- Soluzioni di trasporto ottimali

- Supporto tecnico completo

Domande frequenti

Sei una società commerciale o un produttore?

Siamo un produttore professionale di dissipatori di calore e piastre di raffreddamento ad acqua con una vasta esperienza e un solido team tecnico, con produzione automatizzata e meccanizzata.

Hai esportato merci prima e in quali regioni?

Il 60% della nostra produzione totale viene esportato in Giappone, India, Regno Unito, Canada, Stati Uniti e Brasile.

Quanti dipendenti hai?

Circa 100 dipendenti nei reparti vendite, acquisti, ingegneria, controllo qualità, magazzino e produzione.

Puoi fornire campioni se siamo d'accordo con il design?

Sì, forniamo campioni per la conferma prima della produzione di massa, insieme ai disegni tecnici, se necessario.

Quali metodi di imballaggio utilizzi?

Imballaggio personalizzato con cartoni normali e tessuto a prova di tenuta o cartoni di legno per una protezione ottimale durante il trasporto.

Fornisci supporto tecnico per i problemi relativi ai prodotti?

Tutti i prodotti vengono completamente ispezionati prima della spedizione. Per qualsiasi problema, forniamo soluzioni tecniche immediate.

Vuoi conoscere maggiori dettagli su questo prodotto